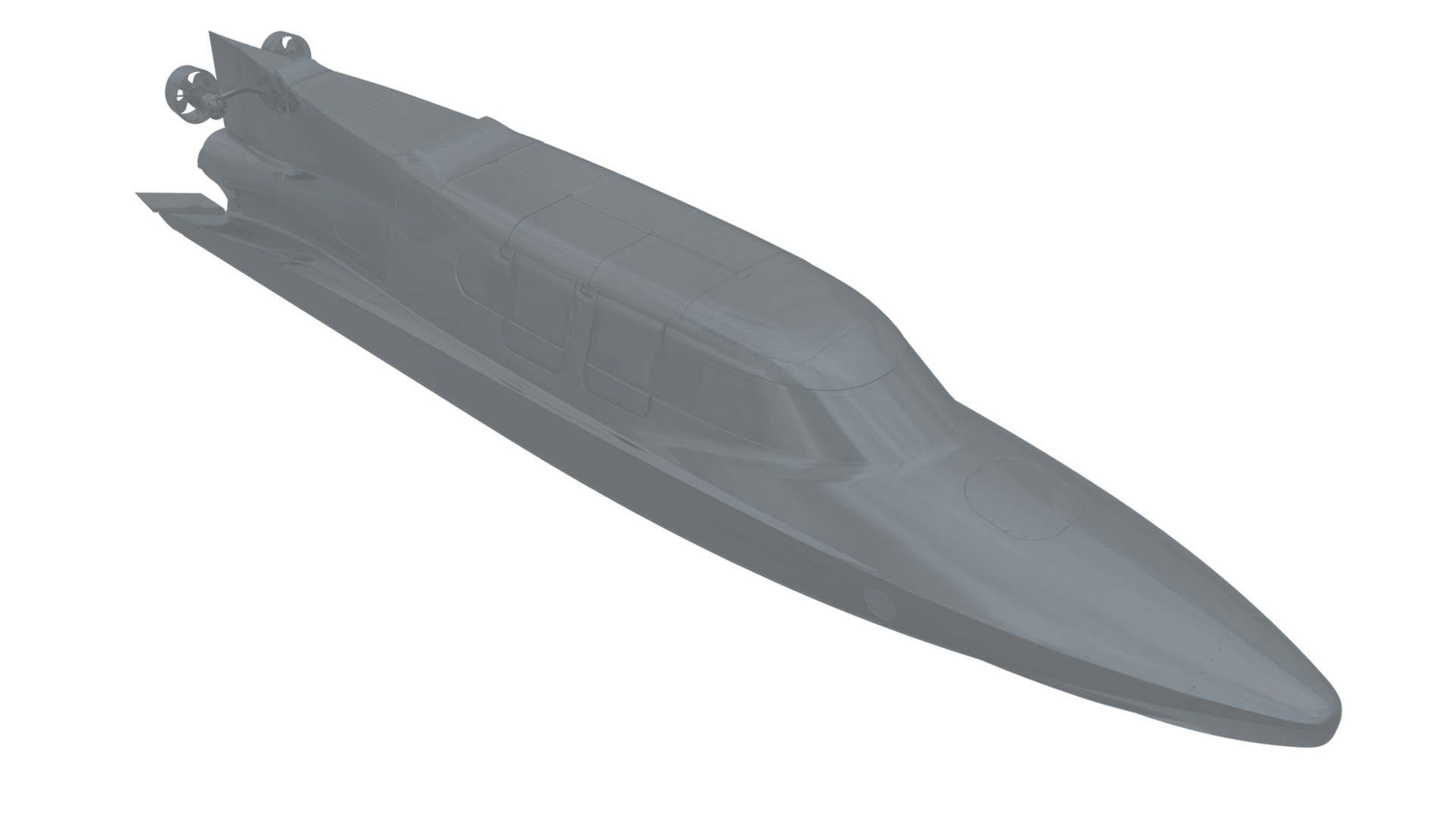

The next generation of covert delivery and mobility

VICTA is a next generation maritime delivery platform capable of a high-speed surface transit before rapidly transitioning to a wet, subsurface mode for covert delivery of operators and/or equipment. The VICTA Class craft is the first of a series of multi-domain platforms which can enable militaries to conduct a range of covert operations and effects delivery. This class of craft has been developed through intensive research with direct input from operators, military strategists, and supporting force elements (deployment and logistics) from around the world. Through the continuous development of our technology and skills, this multi-role platform enables nations to conduct covert operations at range.

The platform is deployable as an individual asset or as a force multiplier, enhancing maritime operations through networked, crewed, or autonomous modes.

Configuration

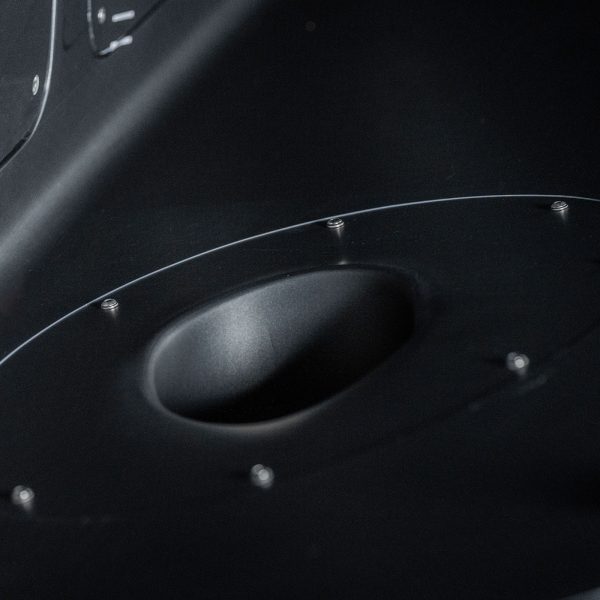

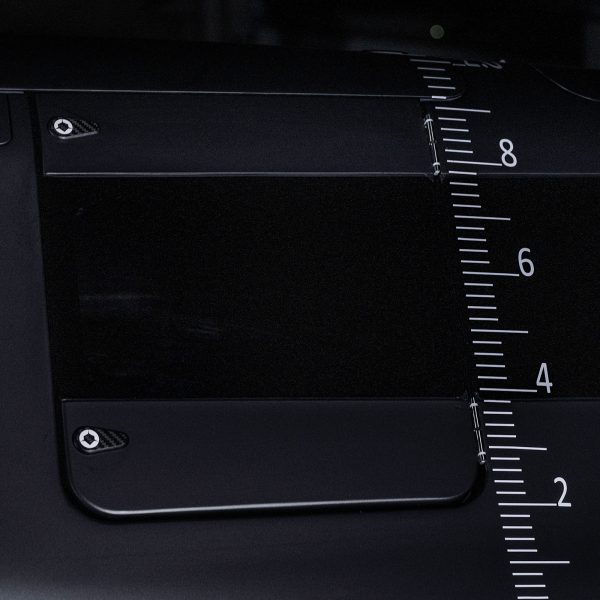

The primary configuration of the current design allows for the clandestine delivery of specialist operators. However, our modular design approach to payload means that the craft is easily configurable. Through a standardised rail system to carry personnel, combat supplies, or alternative mission-specific systems. This flexibility enables multiple mission types across combat functions including: Intelligence, Surveillance and Reconnaissance (ISR); Fires; Manoeuvre; Protection; Command; or Combat Service Support – all delivering tactical effect in support of strategic aims.